Conveyorised Sewing

De-skilling operations and looking at faster, more efficient solutions is what we do.

Automation is one of our key values here at AE Sewing Machines. Our in-house developments have been refined over the years and we are proud to offer them as products under the brand of Advance Sewing Automation (ASA). We've supplied adapted and automated machinery into many different industries and would be happy to take on any new challenges you try and set us!

Past Projects

FAQs

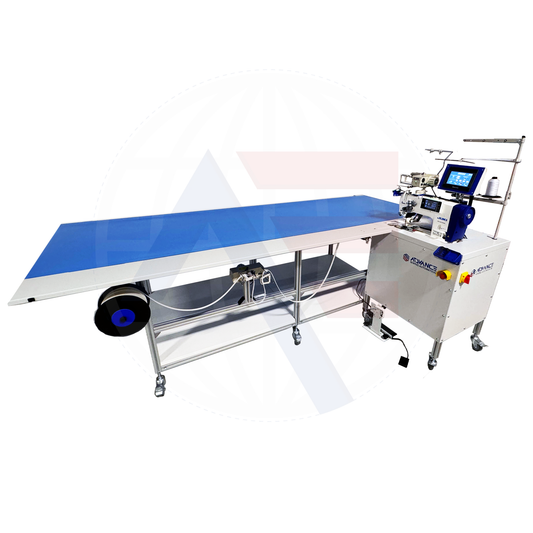

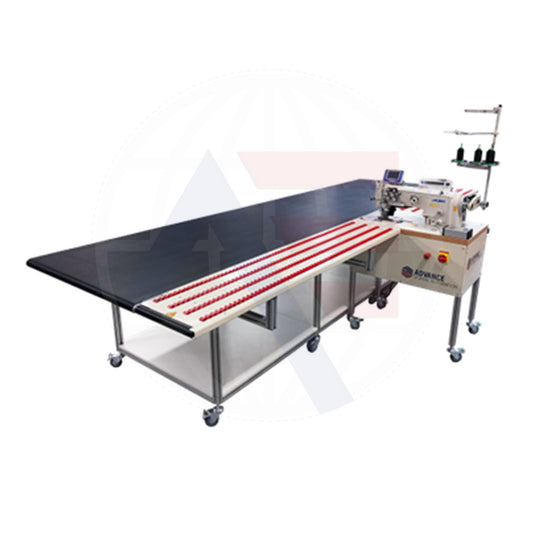

What are Advance Sewing Automation conveyorised sewing machines?

We use the term "conveyors" as an all-encompassing term to describe our automated conveyorised sewing machine systems. Each bespoke conveyor is designed and built in-house by our technicians to automate the process of sewing flat seams, attaching keder/SEG, joining large panels of material, or any other sewing application you can think of. Our systems effectively automate otherwise labour-intensive and time-consuming processes to increase productivity by up to 70%!

How do conveyor sewing machines work?

Similar to a conveyor belt in a supermarket, the material being used is fed evenly through an adapted sewing machine head using a specially developed belt system. Conveyors which are designed for attaching material such as keder edging have a second feeding system built in to accommodate this.

Which industries are these conveyors best suited to?

We have supplied conveyors optimised for a wide range of different applications, from sewing huge stage curtains to attaching keder/SEG edging onto soft signage. Our team are adept at evolving the design to create the ideal equipment for our customers, no matter the industry. If you are looking for an automated sewing solution to improve the productivity of your business, our technicians would be happy to discuss what your ideal setup would be, and if it can be done, we’re the team to make it happen!

What are the benefits of automation?

Automating labour-intensive sewing processes with tailor-made equipment is the best way to increase production speeds whilst ensuring high quality results. Our conveyor systems deskill otherwise complicated and tedious operations, reducing the need for experienced staff who can be difficult to find. We have designed them to be as simple to operate as possible, with minimal human input required to produce accurate and consistent seams every time. On average, customers who invest in our automated conveyorised sewing machines receive a ROI within the first 12 months.

If you're eager to learn more about how we can help improve your manufacturing process, don't hesitate to reach out to us. Simply send us an inquiry by clicking the button below, and we'll gladly engage in a comprehensive discussion about your needs. Whether you're interested in exploring the featured conveyorized sewing machines or envisioning a tailor-made solution designed specifically for your unique demands, we're excited to assist you every step of the way!